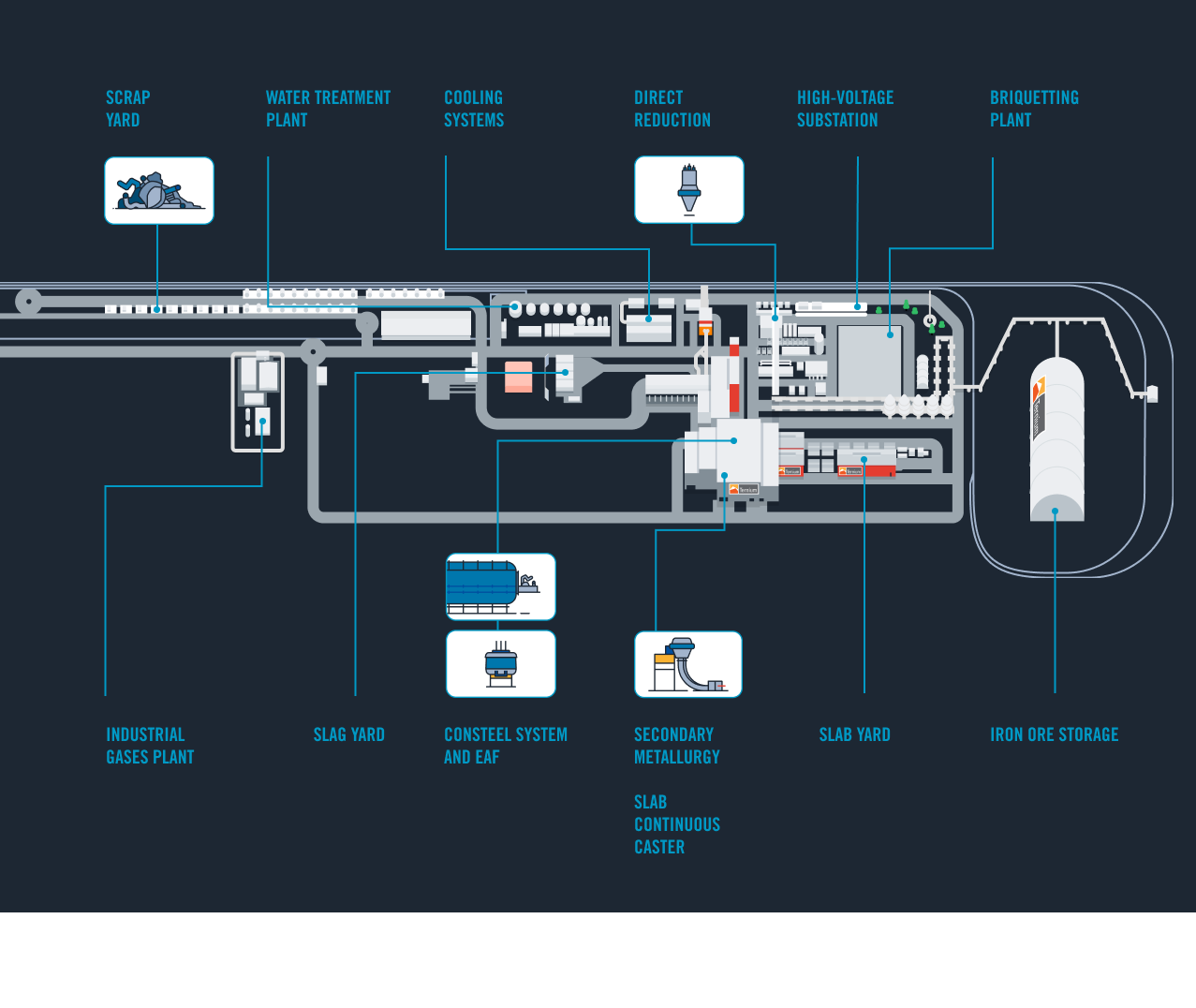

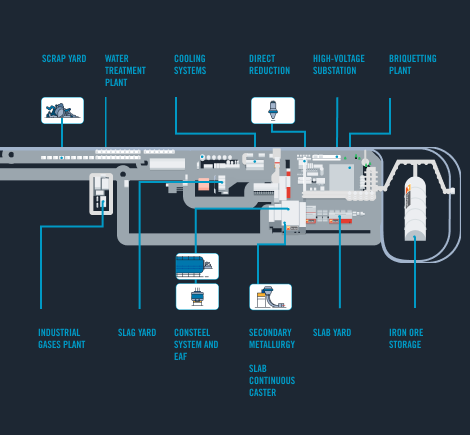

2023 was a further year of expansion for Ternium as we ramped up production at our hot rolling mill at Pesqueria, increased share in a growing Mexican market for flat products, and advanced our positioning in the Brazilian market through acquiring an additional participation in Usiminas and consolidating its results in the second half. At the same time, we initiated a new cycle of investments at Pesqueria that will integrate electric steelmaking and natural gas-based direct reduction of iron ore and additional downstream capacity to further expand the mill’s competitiveness with domestic melted and poured capabilities.

Shipments of steel products rose to 14.2 million tons, a 19% increase over the previous year. Net sales rose to $17.6 billion, with an Adjusted EBITDA of $2.7 billion and margin of 16%, and net income for shareholders, adjusted to exclude a one-time, non-cash accounting effect, was $1.7 billion. Our net cash position at year-end amounted to $1.9 billion after increasing capital expenditures to $1.5 billion and, at the annual shareholders’ meeting, the annual dividend payment was increased by 22% to $3.30 per ADS.

The Mexican market for flat steel products from the industrial sector is growing, and expected to grow further with investment in manufacturing capacity for nearshoring activity, while investment in industrial warehousing, pipelines and infrastructure projects remains at a positive level. We continue to increase the production capabilities for finished steel products at our state-of-the-art industrial center in Pesqueria, with new finishing lines such as the pickling line we have just started up, complemented by our R&D center where we are increasing our product development activities. Already it is an essential pillar for the development of Mexican industrial production, and, once we complete our project to integrate electric steelmaking and a hydrogen-ready direct reduction unit, the carbon emissions content of its advanced steel products for the auto industry will be less than those of most of its global competitors.

The increase in our participation in Usiminas coincided with the relining of its main blast furnace at Ipatinga. This substantial modernization of the facility was an opportunity to increase its production capabilities and improve its energy efficiency and productivity, reducing costs, carbon emissions and environmental impact. We will continue to work on improving Usiminas’s profitability and the productivity of its operations, as well as its positioning in the Brazilian market for flat steel products, where we see considerable potential for long-term growth in industrial production in a country whose apparent steel use is half of that of Mexico.

The risk of unfairly traded imports of steel products from China, however, looms large over the the Brazilian steel industry and that of other Latin American countries. With the slowdown of the Chinese economy and steel demand, exports of steel products from China have risen above 100 million tons over the past 12 months. Exports of Chinese flat steel products to Brazil, in particular, have risen strongly in the year to date and already exceed last year’s total, accounting for over 80% of Brazil’s imports of such products. Although Latin American governments, including that of Brazil, are introducing measures to stem such imports these measures may prove to be insufficient.

In Argentina, restrictions to the access to foreign exchange imposed by the previous government affected our operations and those of our customers. The new government is attempting a substantial transformation of the economy and its longer-term competitiveness but with the short-term impact of a significant downturn in activity as it acts to eliminate the fiscal deficit and eradicate runaway inflation. If the government is successful in its efforts to stabilize the macroeconomic situation and deregulate the economy, the country should resume economic growth and development after many years of stagnation.

As part of our decarbonization program, we acquired additional grid access rights with which we are increasing the capacity of our wind farm under construction in Argentina to 99 MW. Upon completion which is expected at the end of 2024, the wind farm will provide 90% of our current requirements for purchased electricity at our Argentine operations.

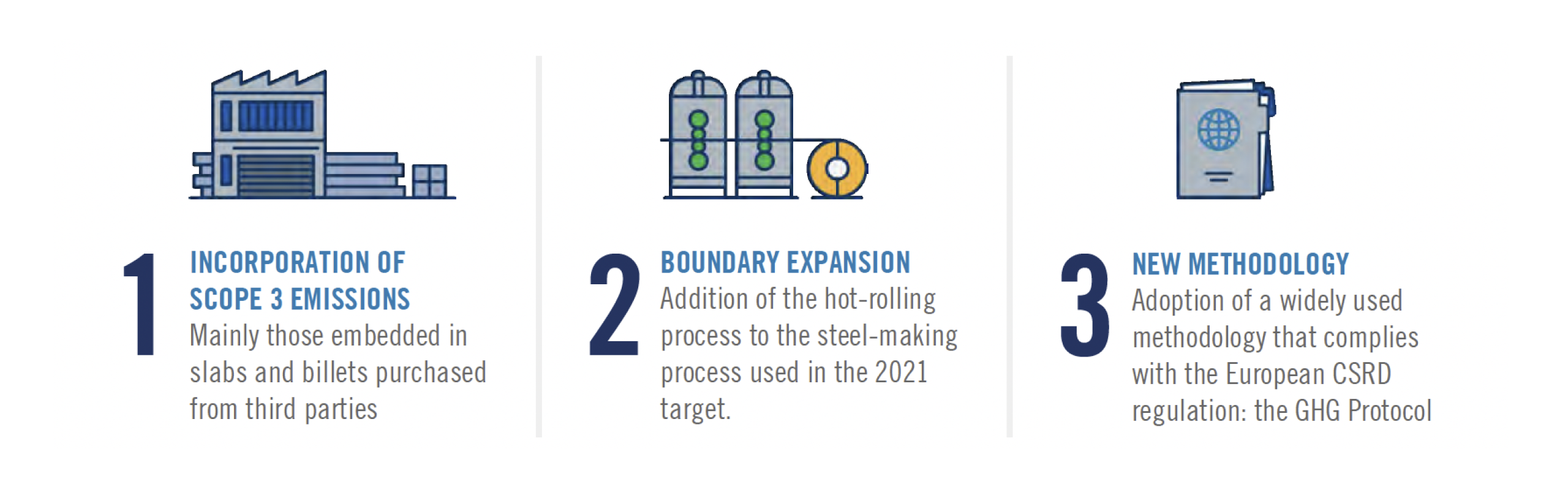

We have modified the decarbonization target that we established in 2021 so that it now includes Scope 3 emissions for raw materials and emissions up to, and including, the hot rolling process. We will also measure emissions using GHG methodology. The modified target is to reduce our emissions intensity by 15% by 2030 taking 2023 as a baseline. Since the modified target more closely reflects the scope of our actual operations and emissions, it will improve reporting transparency.

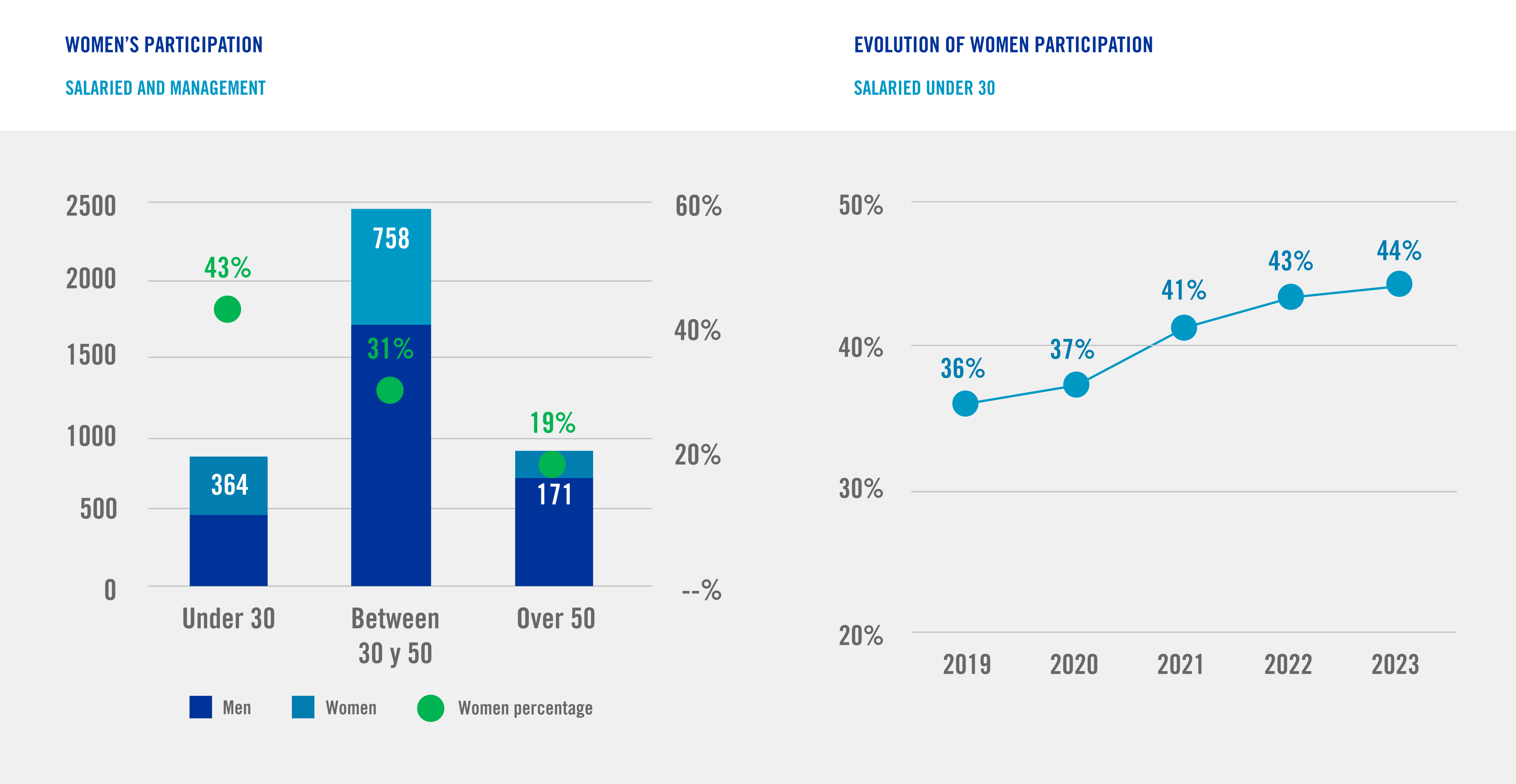

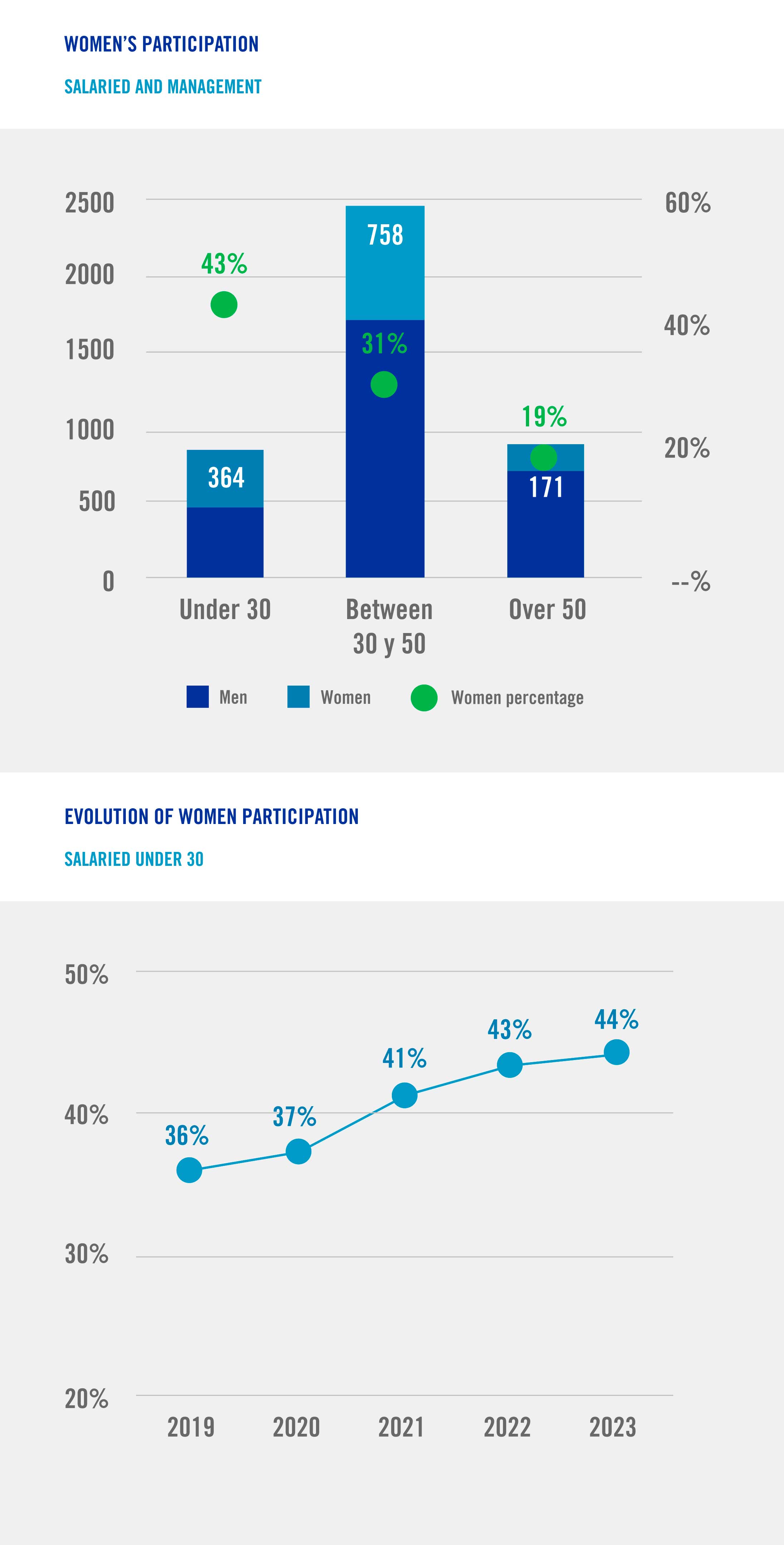

Ternium and Usiminas employees add up to 35,000. Together, we make a substantial contribution to numerous communities across Latin America. Throughout our operations, we aim to provide a dynamic and respectful working environment where employees are provided extensive training to perform their functions safely and effectively and are encouraged to develop their potential with continuous learning.

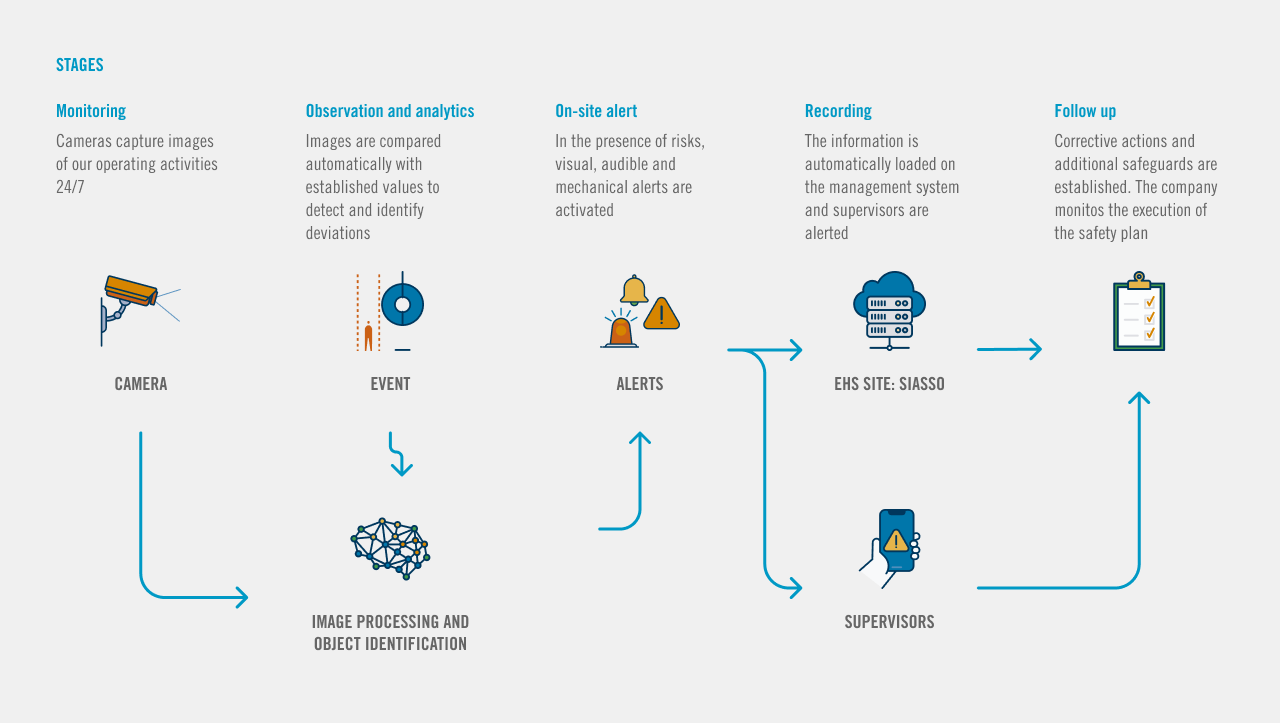

Ensuring a safe and healthy working environment is always our priority. We work tirelessly to instill a culture of safety first with all of our employees understanding their role and responsibility. A relentless focus on analysis of potentially hazardous incidents and preventive actions, is backed up by investments to improve material flows and working conditions and rigorous training, particularly for contractors and new employees. To make our training more impactful, we are using new technologies such as virtual reality, and, this year, we received a worldsteel Steelie award for excellence in education and training for the safety training program we developed at Ternium Brazil. We deeply regret, however, that, during 2023, two fatalities occurred in Ternium’s operations and one in those of Usiminas. Each and every fatality is a cause for deep reflection about what we could have done better to avoid it and a reminder that there is always more we can and must do to improve the safety of our workplace.

Support for technical education and making educational opportunities more inclusive is at the core of our community support activities. The Roberto Rocca Technical School in Pesqueria, now in its ninth year, provides technical education for 400 students and has established itself as a center of excellence in this growing industrial center. We have remodeled the classroom spaces to encourage a more interactive form of learning and to facilitate its use by other students and members of the community, particularly those aiming to attain certain specific technical certifications. Our new school under construction in Santa Cruz, next to our slab mill in Brazil, will open its doors next year and use the same educational principles and learning methodologies as its sister schools in Pesqueria and Campana.

In this report, you can learn more about the values and activities, and their governance, that are integral to the long-term sustainability of our company. As we grow and extend our industrial footprint across Latin America, we do so while sharing sustainable values and principles with a resolute focus on strengthening the positioning and competitiveness of our operations. These include a focus on health and safety, respect for the environment, quality and excellence in our products and services, the development of our local communities and a competitive value chain, and developing an engaged and diverse team.

Our employees are at the center of our efforts and achievements. I would like to give a special thanks to them for their ongoing efforts and achievements over the past year. I would also like to thank our customers, suppliers and shareholders for their continued support.

September 2024